A new, small-scale test installation has been designed to study Rolling Contact Fatigue (RCF), the metal fatigue that occurs due to the contact between railway tracks and the wheels of rolling stock. This new installation aims to enable better analysis of rail performance during rolling contact, providing more insight into RCF defects in particular. The installation simulates, at scale, the running conditions of a wheel on a circular track in a way that accurately represents real-world wheel-to-rail contact.

In this new setup, continuous testing of wheel and rail materials (with or without existing damage) can be conducted under load conditions typical of railway operations. Essentially, the test installation consists of wheel components that, powered by two electric motors, can move across a flattened ring-shaped rail.

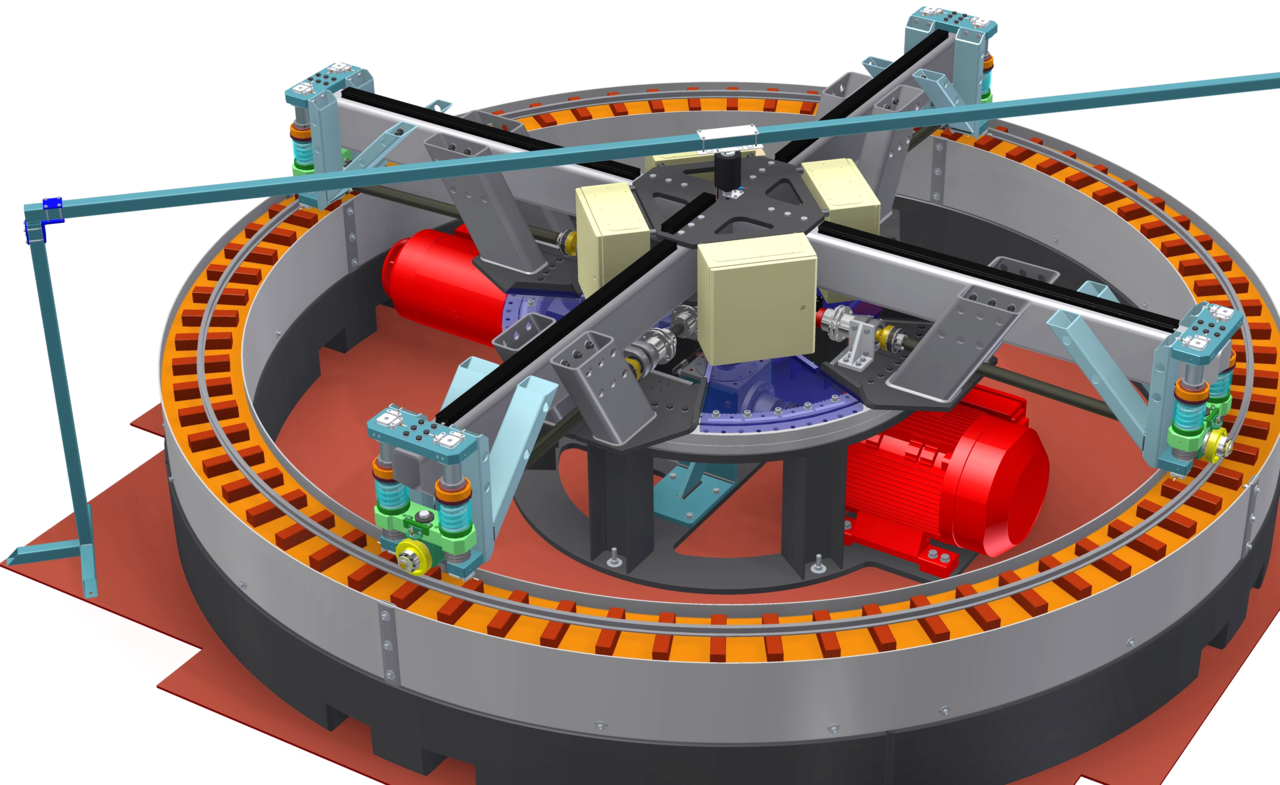

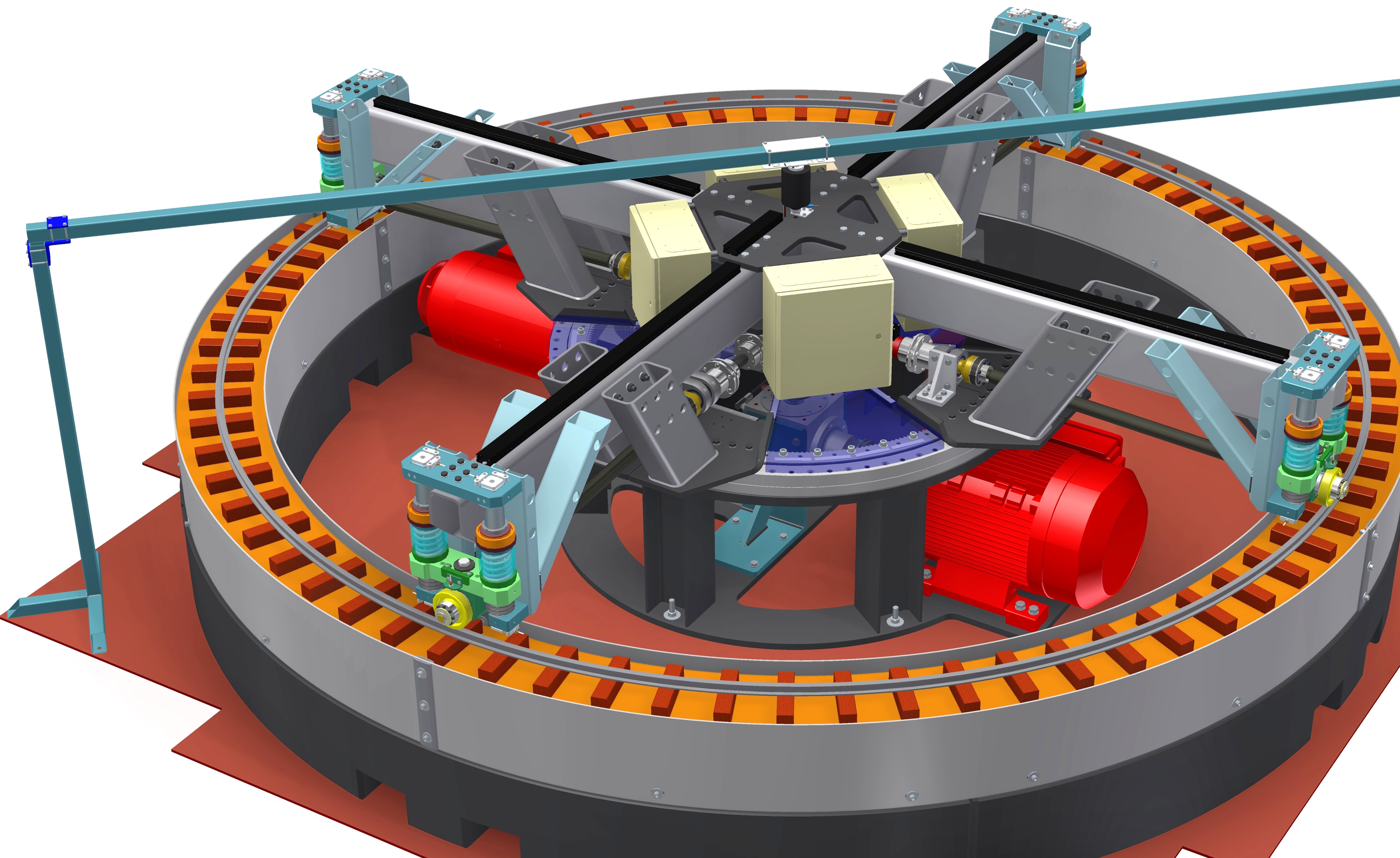

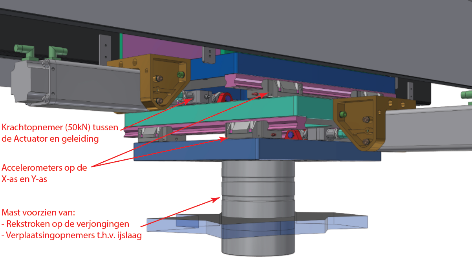

Based on this information, DEMO developed several conceptual designs. From these, the best options were selected, and ultimately, this design was chosen:

A scale model of an actual rail is bent into a 4000mm circle. Just like a real railway, the rail is fixed onto wooden sleepers, which rest on ballast or a similar material. Four wheels are attached to a large, sturdy frame. This frame can be driven by an electric motor up to 56 rpm. The four wheels themselves are connected via gearboxes to another electric motor.

Since the frame and wheels can be driven independently, scenarios such as continuous braking or continuous acceleration with wheel slip can be simulated. The wheels are pressed hard against the rail with springs to simulate a heavy axle load.

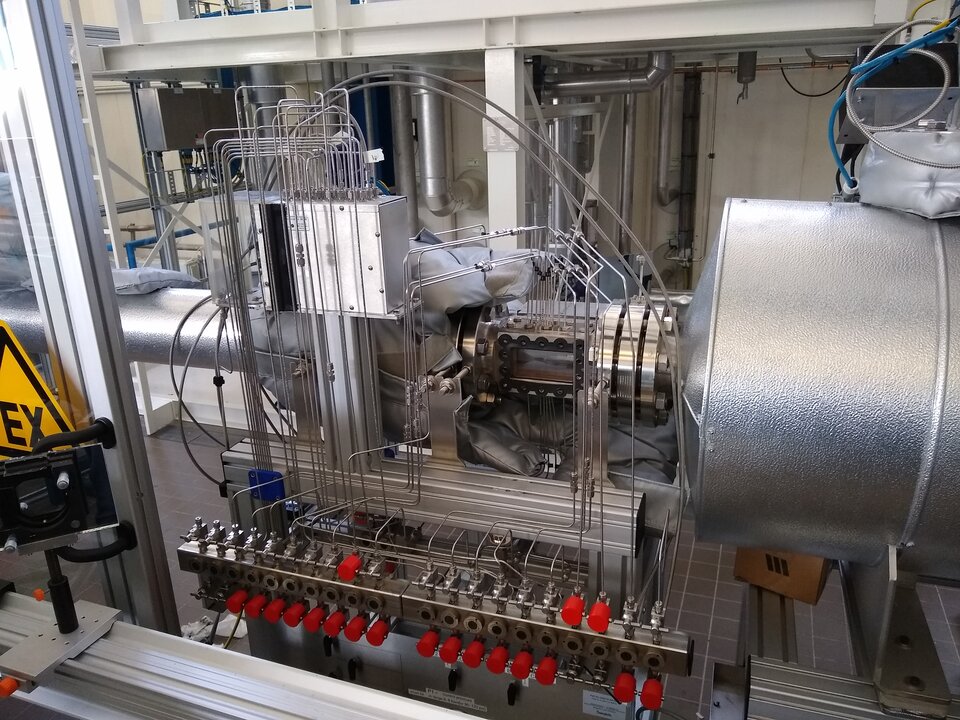

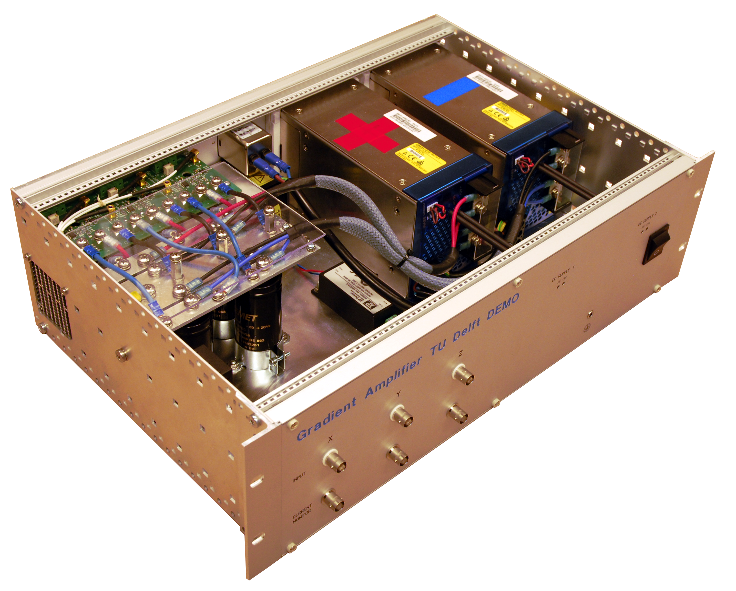

DEMO was responsible for both the complete electronic and mechanical design. A large number of DEMO employees are involved in constructing the setup.