For FC, oxidizer must be diluted (a low O2 content is created by adding inert gases such as nitrogen and CO2) and reactants must be preheated above the auto-ignition temperature. This results in a combustion regime with low-peak temperatures and broken reaction zones, resulting in low NOx emissions. The long-term goal of this lab is to develop FC for gas turbine applications.

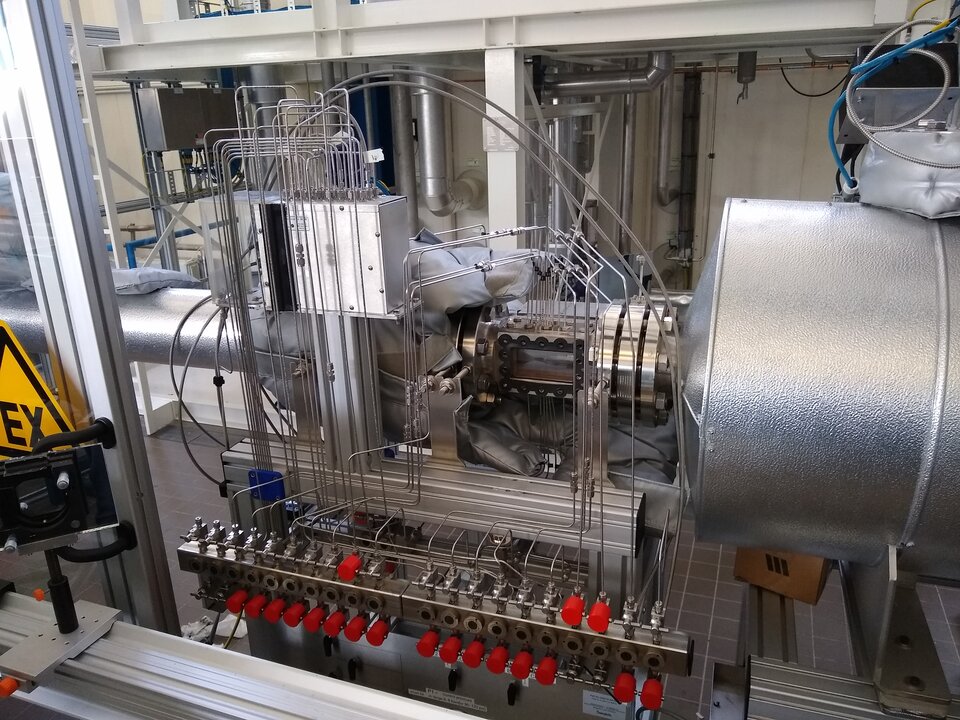

In the current combustion chamber design, high-speed beams enter the chamber in a location radially relative to the central axis, leading to internal recirculation zones.

This allows hot burnt product gases to be recirculated towards the entrance, so that fresh gases can be both diluted and preheated. In the burner head, the fuel and air jet are coaxially arranged, resulting in a partially premixed mixture at the outlet of the jet in the chamber. The exhaust gases are cooled by the addition of air before being discharged through an exhaust gas pipe.

Optical access is obtained by using a quartz tube as a combustion chamber or a steel chamber with quartz windows (when the pressure is higher).

The set-up is an installation to study flameless combustion (FC) by creating relevant conditions for this in a controlled manner and using optical diagnostics to carry out measurements.

DEMO has built this set-up from a flow chart and, needless to say, in consultation with the client. There had to be enough space for the optical measuring instruments, whereas the set-up had to remain as compact as possible.

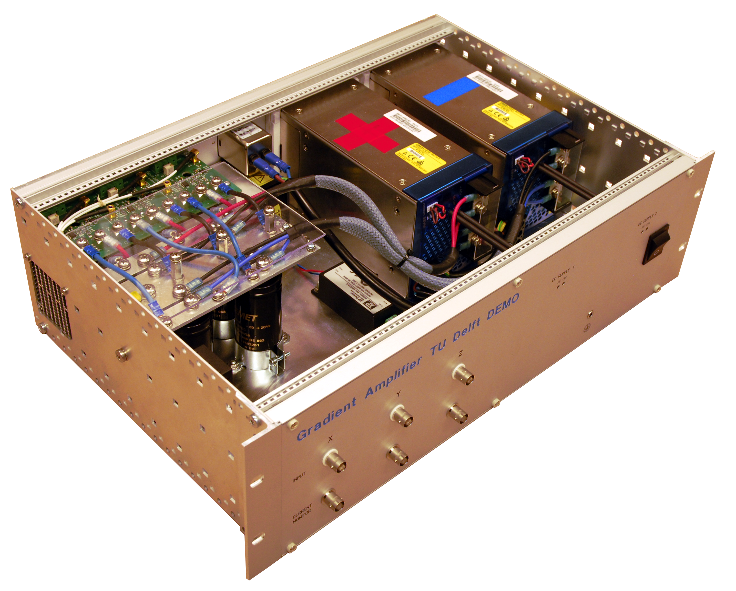

Electronics engineers at DEMO also work on this project and there are regular discussions with the client to get input for the flow charts.