Materialising Futures

The Materializing Futures section develops theories, tools, and methods for understanding and designing with emerging materials and fabrication technologies. We strive to achieve a positive impact on the planet and society through our research, which is organized under three interconnected pillars: Materials, Computation, and Fabrication.

design for sustainability / materialising futures / knowledge and intelligence design / labs / people / contact

Materials

The definition of materials in design is more expansive than ever. Materials can possess life-like properties: they can sense and adapt through mechanical, computational and biological programmability. As materials become increasingly life-like, responsive and adaptive, they acquire new functionalities and expressive capabilities. How should designers work with them? What new skills and competencies do we need to fully utilize their capabilities? What novel tools and techniques must we develop to better understand and convey the potential of such materials to future designers?

The main research activities within this pillar are concerned with cultivating an understanding of the potential of smart and living materials for product design, so as to support and inspire future design research and practice. Our researchers adopt a material-driven design approach, in which making and tinkering with materials is central to the process. This approach also applies techniques to understand and integrate the technical properties and experiential qualities of a material (how it is perceived by end users) in pursuit of its design potential. Specific research topics under this pillar include design guidelines for shape-changing materials and interactive textiles, designing living artefacts, textile-based sensing, capturing and modelling adaptive material appearance, scaling-up research with living materials, collaborative material development, novel material experiences and societal acceptance of life-like materials.

Computation

By combining the ‘intelligence’ of advanced algorithms with the power of modern digital hardware, computational approaches can help designers explore a solution space in a systematic and comprehensive manner. The role of computational tools in design is gradually evolving beyond the established approach of computer-aided design (CAD). One of the main research activities within this pillar is the development of novel algorithmic approaches that will soon make it possible to have the computer to create the design with human guidance.

Another major area of activity focusses on creating digital twins of objects or systems and developing approaches to utilize these detailed computational clones in all phases of the design process. Not only do our digital twins incorporate data derived from the object or system itself, but also from the user and user groups.

Specific research topics under this pillar include ultra-personalized products, topology optimization, generative design, digital twins, 3D-scanning, computational tools for modelling human bodies and behavior, smart materials, printed electronics, and digital-biological hybrids (living materials).

Fabrication

The field of design will be revolutionized by the incorporation of disruptive new fabrication technologies. We anticipate that both computational and biological approaches will be central to many of these future fabrication technologies. Accordingly, our fabrication related research activities are organized under two main areas of activity, namely Digital Fabrication and Biofabrication.

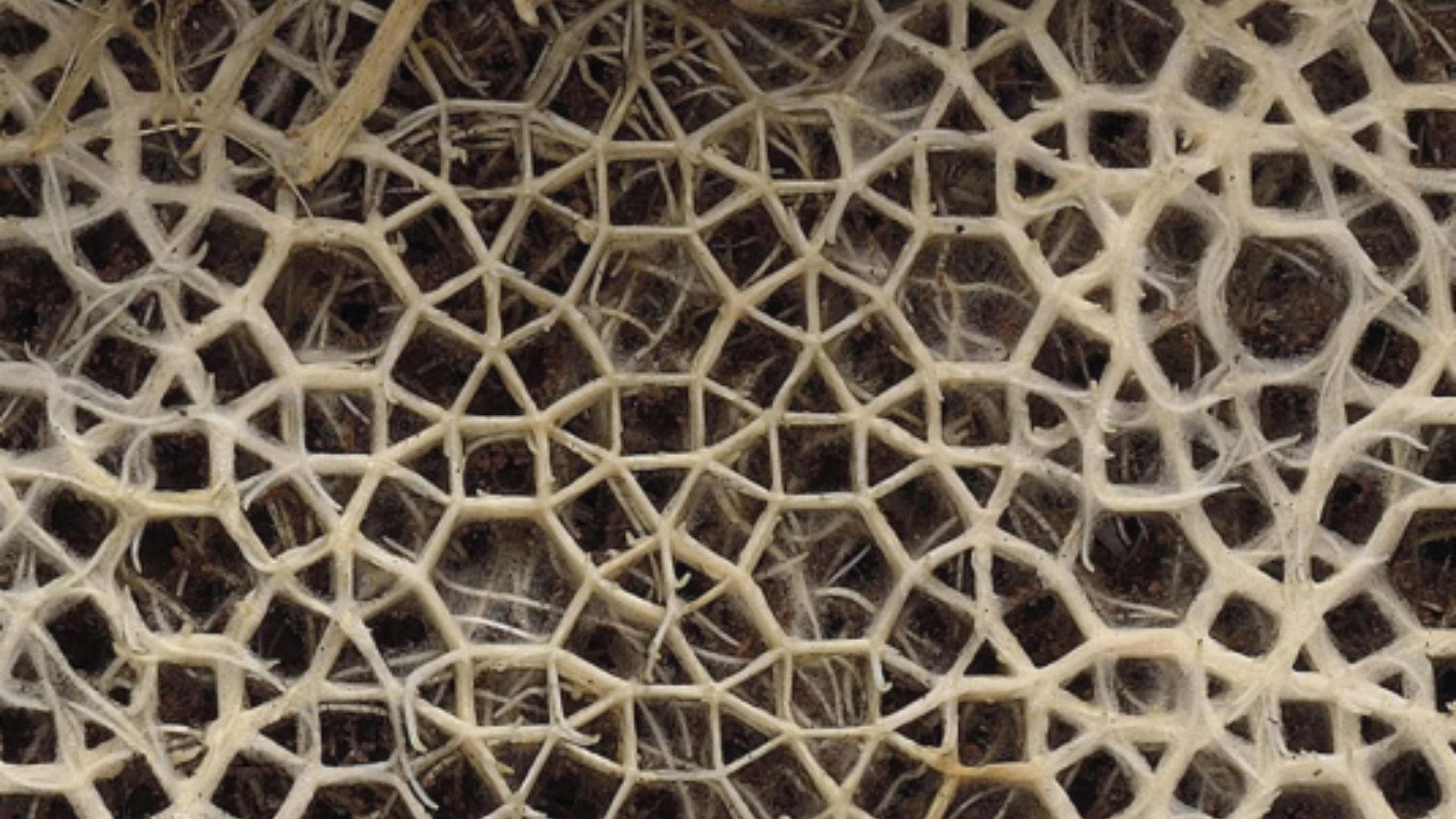

In digital fabrication processes, the physical manufacturing hardware is driven by digital data, thereby autonomously creating the physical geometry from a computer model. This near-seamless translation from digital to physical allows rapid design iteration, limitless potential for customization and the creation of extremely complex geometries. One such approach, additive manufacturing (3d printing), is maturing to the point of being applicable to end-use products in many different areas, from human organs to aircraft components. Along with the growing variety of materials that are being introduced to these processes, the continuing evolution of additive manufacturing is giving rise to possibilities to combine multiple materials, including smart materials, into a single structure.

Specific research topics within digital fabrication are the development and effective application of techniques, including multi-material 3D printing, 3D printed metamaterials, 3D printed electronics, and bioprinting

Research themes

Projects

Labs

Education

Bachelor courses

Master courses

Graduation opportunities

- Digital / on location

- Supervisor: Dr. ir. Willemijn Elkhuizen

- Envisioned start date: January/February 2023

Graduation project examples

People

Kaspar Jansen

- +31 (0) 152786905

- k.m.b.jansen@tudelft.nl

-

Room B-3-170

Peter Vink

- +31 (0)15 27 81438

- P.Vink@tudelft.nl

-

Room 32-B-3-160

"Sustainable productivity can be reached by adapting environments to human and organisational characteristics."

News and Updates

- [October, 2022] | Great headline here. Read here.

- [October 24, 2022] | Great headline here. Read here.

- [March 29, 2022] | In the spotlight: Dr. Achilleas Psyllidis. Read here.

- [February 24, 2022] | Interview with Jacky Bourgeois about the course ‘Digital Product Development’. Read here.

- [February 1, 2022] | The creative breeding ground of Delft Design Labs. Imagine a research environment fuelled by creativity, where people from different disciplines and varying levels of expertise collaborate, seeking new insights and solutions that can change the world. That is what you’ll find in the Delft Design Labs, a theme-based research platform at the TU Delft Faculty of Industrial Design Engineering (IDE) that brings researchers, students and external partners together to find innovative solutions to the complex challenges of our time. Read more here.