From The Start: The Early Design Bird Gets The Remanufacturing Worm

The circular economy. Sustainability. Refurbishment. Remanufacturing. Recycling. We hear these buzzwords used all the time when talking about how humanity needs to lessen its impact on the planet. For her PhD research, Nina Boorsma looked into how to get companies to make more sustainable products and found that the process needs to start early.

From BSc student to PhD candidate

The Dutch researcher began her academic journey at the Faculty of Industrial Design Engineering (IDE) with her bachelor’s degree. “I had an idea about doing something with sustainable design in the back of my mind,” Boorsma says. She focused on that for her minor, and then continued at the faculty to get her master’s in Strategic Product Design (SPD).

After graduation, she took a detour to work in marketing and communications at a Dutch product design agency and then at an innovation consultancy. Boorsma says these roles ended up being very useful to her overall understanding of how companies like that work. “I could really take a look and see what they were doing,” she says. One important takeaway - that clients don’t come in asking for projects to consider remanufacturing - would play a prominent role in her PhD research.

Remanufacturing: its serious business

For her PhD, she joined a project at the faculty funded by ReCiPSS, a four-year-long European Union research project focussed on setting up and demonstrating circular manufacturing systems for used car parts and white goods. The project, conducted in coordination with several large manufacturing companies, wanted to look at how to create and optimise circular business models. Initially, Boorsma thought she would fully focus on developing design methods for remanufacturing but ultimately found herself working on circular product design in a broader sense.

Remanufacturing, according to Boorsma, is not like the more superficial sprucing up an iPhone might undergo before being sold as refurbished. “They really check every single part,” she says. This detailed examination and regeneration process “remanufactures” the product into something that has the same performance, quality, and safety standards as the original.

A proven business case

Unlike other circular economy approaches, remanufacturing is one of the strategies with a proven business case, at least in professional products. It has been in use in Europe since the 1940s for things like automotive engines, manufacturing equipment, and hospital machinery. According to Boorsma, the engineering knowledge about remanufacturing isn’t lacking. Yet companies are still not implementing this knowledge in the design process.

Boorsma points to hospital MRI machines as an example. In the Netherlands, hospitals often buy some of the newest MRI machines. These premium products have all the bells and whistles. But for many patients with very straightforward complaints, the latest and greatest MRI may not be necessary. So, hospitals also buy remanufactured MRI machines, which have fewer features but can service patients with uncomplicated diagnostic needs.

Introducing design processes from the start

For her portion of the ReCiPSS project, Boorsma looked into what role the early-stage design process plays in the implementation of remanufacturing. Drawing on her understanding from working at design agencies, she knew that companies often don’t initially consider remanufacturing, or other sustainable design choices, in their design process. “And we found it becomes much harder to push for it later,” she says.

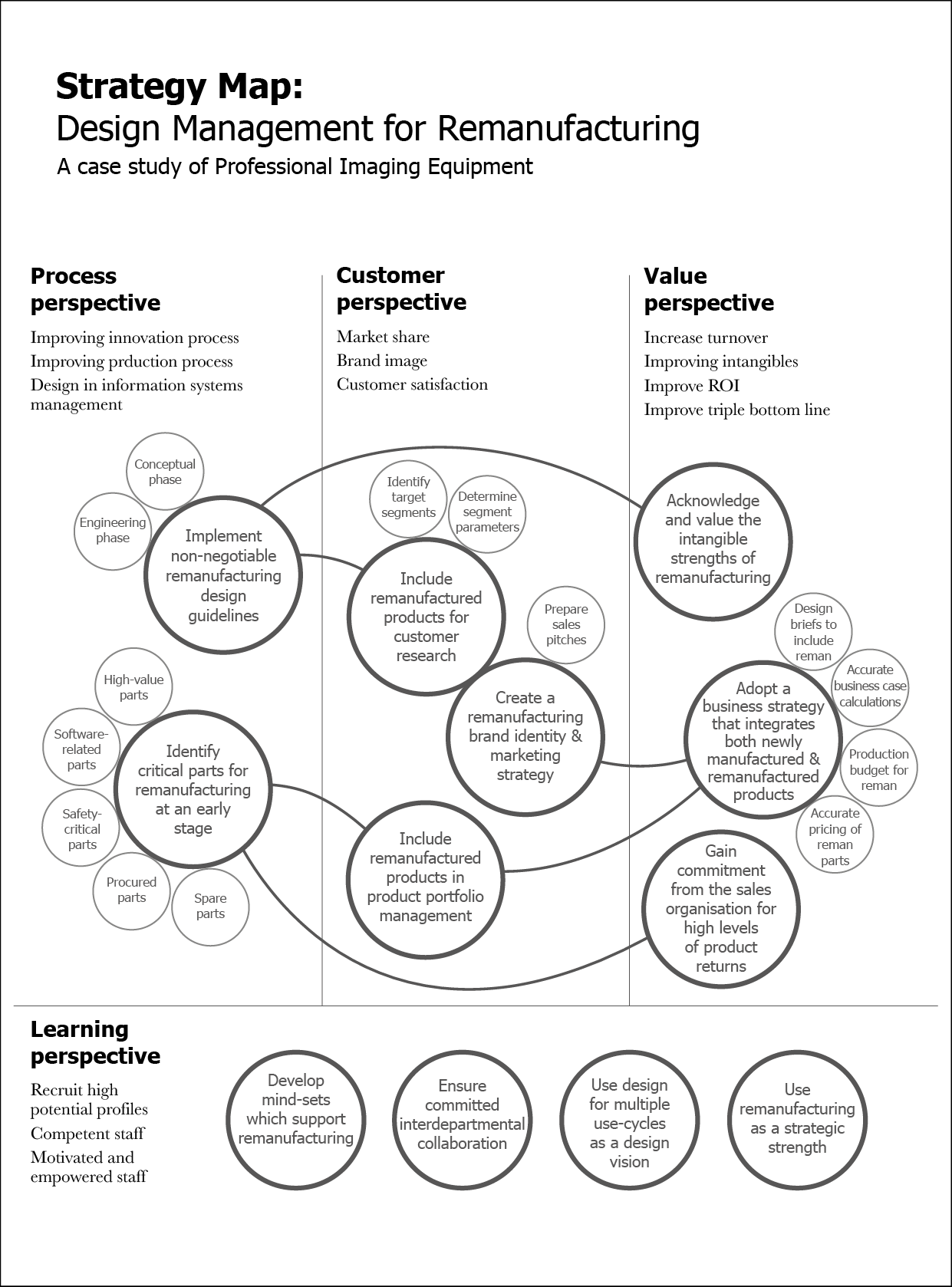

Her ultimate contribution, included in her thesis titled ‘Strategic design for Remanufacturing’, was an assessment method intended to be used by design teams at the outset of projects. “We wanted to help give the team a starting point,” she says.

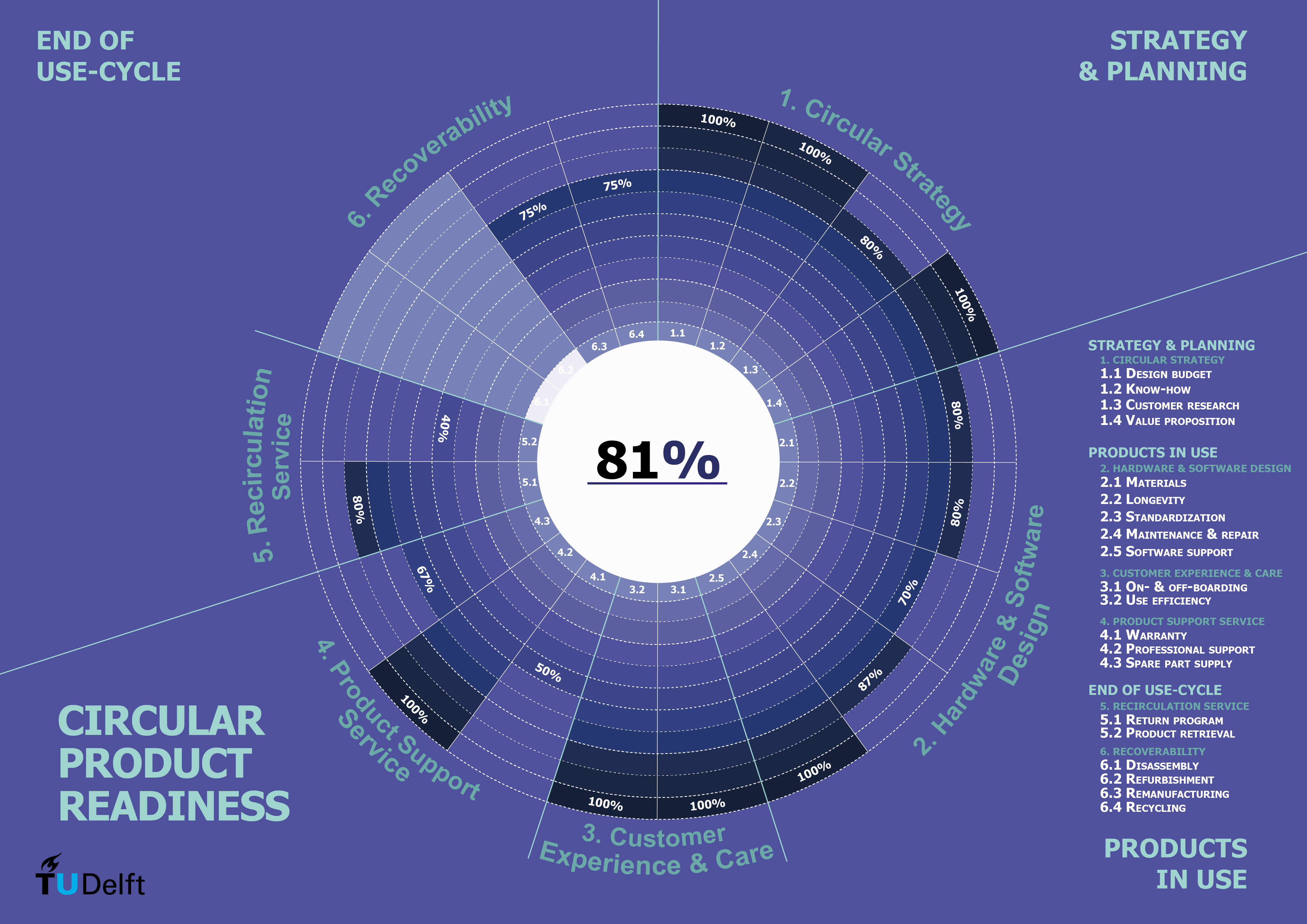

Circular Product Readiness

The protocol, called Circular Product Readiness, consists of 63 questions divided into six sections. It covers everything from spare part supply to return processes. Boorsma relied heavily on design management theory in her research. The approach aims to develop a business environment which allows a company to achieve its strategic goals and relies on design, strategy, project management and supply chain techniques to build the process.

Team work makes the dream work

Boorsma really emphasizes how so much of her PhD journey was made easier by working together with a great team. “I really felt at home,” she says. Both her colleagues and her advisers, she says, lessened the difficulty of the often challenging process of research.

When asked what advice she would give to a friend considering doing a PhD, she stressed that for her, the team and her own desire to learn more about the subject were the two most important factors in knowing that getting her PhD was the right decision. “You have to want more time and space with a topic,” she says.

The next step

She has now started a post-doc position just down the road at the Faculty of Architecture & the Built Environment in the Architectural Engineering and Technology department. Her new research project works together with two other universities, one in Hungary and one in Finland, to set up a research hub around sustainability and the circular economy with the further goal of developing better relationships between researchers in Eastern and Western Europe.

And, Boorsma has already seen her assessment tool being used. “That is something that I am really, really happy about,” she says.

Ruud Balkenende

- +31 15 27 81658

- a.r.balkenende@tudelft.nl

-

Room B-3-310

Conny Bakker

- +31 (0)15 27 89822

- C.A.Bakker@tudelft.nl

-

Room B-3-330