Chips on paper

Mizusense is a startup working on biodegradable chips that are printed on paper. As an initial application, the company focuses on agriculture, where inexpensive sensors can significantly reduce water consumption.

By Jurjen Slump • November 5, 2023

Bugra Kuloglu calls in from his hometown of Zongudak (Turkey) from where the still young company is run. He’s working on a first round of investment and, once that is closed, he wants to open an office in the Netherlands. He’s no stranger to the country and Delft in particular. Before founding Mizusense, Kuloglu led Appsilon Enterprise, which is located in NEXT Delft. The company produces diamonds that are grown in a laboratory and can be used in applications for quantum computers and sensors.

Bugra, going from growing diamonds to biodegradable chips is quite a step. How did you get to this point?

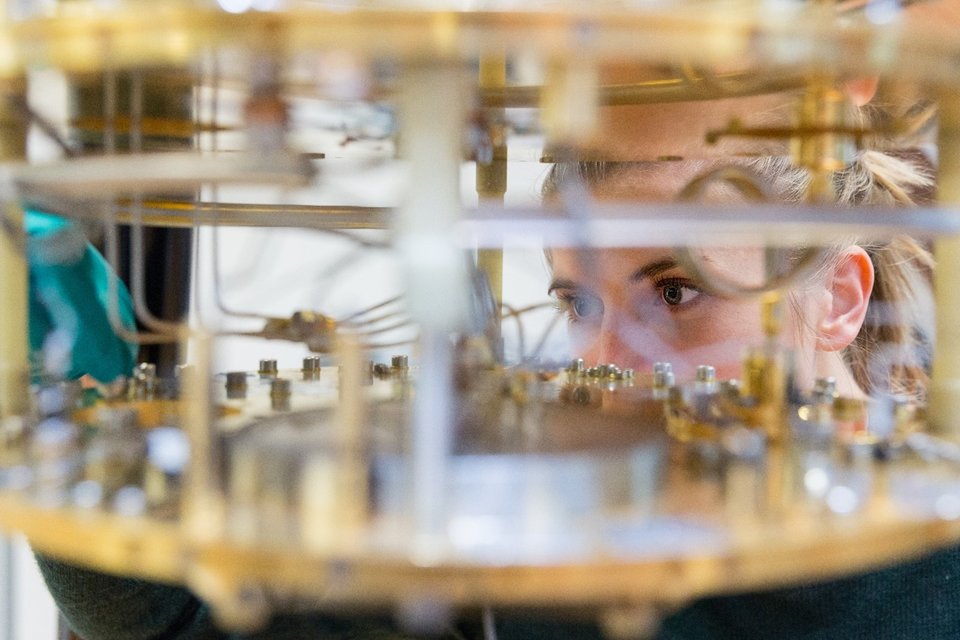

“That is thanks to Ryoichi Ishihara, the co-founder of Mizusense. He’s an associate professor at TU Delft and is also involved in QuTech, where he works on the application of synthetic diamonds in quantum computers. That's how I got to know him at Appsilon. However, he also has a groundbreaking invention to his name when it comes to printing chips on paper. My journey at Appsilon came to an end last year and I then decided to work with Ishihara to commercialize his invention. He as Scientific Advisor, me as CEO.”

What does Ishihara's invention consist of?

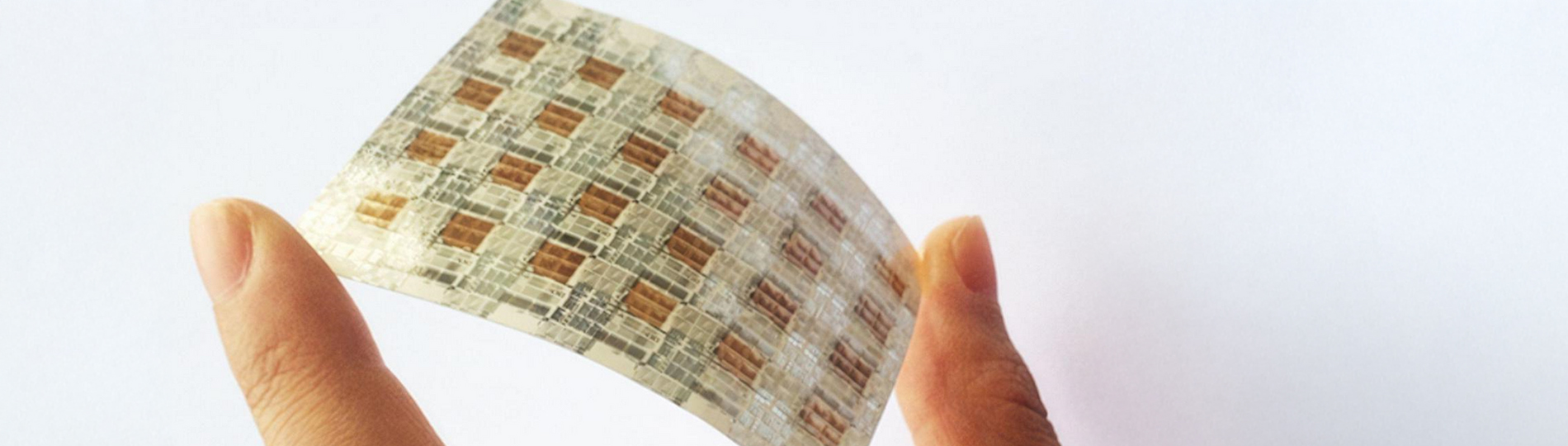

“Ishihara was the first to successfully print a silicon chip on biodegradable paper. This brings a series of new applications within reach. Think of displays on a milk carton that show the shelf life. Printed electronics on paper are much cheaper and much better for the environment. The scientific challenge was to print the chips on the paper without it catching fire, which Ishihara and his team have succeeded in doing using a groundbreaking new technique.”

Printed electronics have been around for a while, think of sensors to measure tyre pressure. What added value will Mizusense offer, apart from sustainability and lower costs?

“Existing printed electronics do indeed have numerous applications. However, those are semiconductors printed with organic materials or metal oxide and lack the performance of silicon in terms of reliability, energy consumption and electronics. That’s why it has been difficult to develop products for agriculture, for example.”

Mizusense focuses on agriculture. Why?

“Water scarcity is a major problem globally. It leads to high irrigation costs in areas with little water and where farmers depend on desalinated seawater. We want to develop the first biodegradable moisture sensor for agriculture, which forms the basis for an irrigation schedule. This allows arable farmers to save 40 per cent on water. There are a total of 90,000 hectares of greenhouses in Agadir (Morocco) and Almería (Spain), which together use nearly 1 billion cubic metres of water. With our sensor, farmers can save up to 3,000 cubic metres per hectare.”

Is it really that important that the sensors are made of paper and therefore biodegradable?

“Yes, paper is inexpensive and will greatly reduce costs. It will be the cheapest chip in the world. The biodegradability also ensures that maintenance costs are reduced, because you can simply leave them in the ground and they’ll be gone after three years. Moreover, these sensors do not affect the soil.”

Why do you want to establish Mizusense in the Netherlands?

“The Netherlands is a pioneer in both semiconductor and agricultural technologies and we are in the ideal innovation ecosystem here to develop and implement this technology. TU Delft offers the right ecosystem to develop new semiconductor technologies and, at Wageningen University, we participated in the acceleration programme for agriculture. This enables us to benefit from the networks and expertise of both universities.”

What else can you do with printed biodegradable chips? What does the future hold?

“This technology paves the way for many innovations. Think of clothing equipped with sensors or the production of low-cost, flexible solar panels and a supercapacitor that can be used instead of a battery. Biodegradable chips are also suitable for use in healthcare, such as detecting diseases in the human body. And all that at extremely low costs.

Interested in collaboration?

Interested in business collaboration or seeking knowledge and insights on your policy themes?

Contact us

![[Translate to English:] [Translate to English:]](https://filelist.tudelft.nl/_processed_/5/3/csm_TWIGA_9c8e88c4d7.jpg)