How living materials from algae can best capture carbon

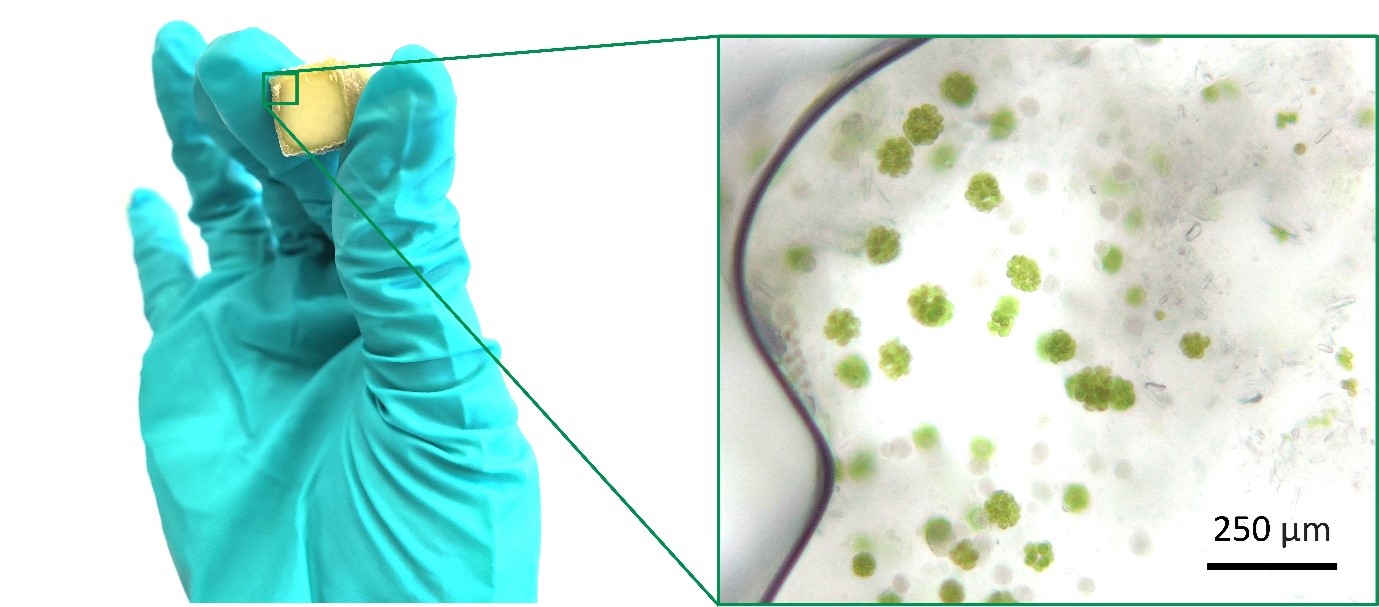

Scientists from TU Delft have found how confined microalgal cells grow optimally in photosynthetic engineered living materials. With the use of light energy, the microalgae convert CO2 from the air into sugars, energy and oxygen for their survival. Such algae-based living materials could be used in a range of applications, from functional objects for CO2 capture, to oxygen sources for biological tissues. The team, led by Marie-Eve Aubin-Tam and Kunal Masania, present their new insights in Advanced Materials.

“Engineered living materials (ELMs) are an exciting new class of materials that have the potential to revolutionise society”, biophysicist Aubin-Tam explains. “An example is photosynthetic living materials, in which organisms grow that actively photosynthesise.” In nature, many bacteria, algae and plants photosynthesise; they take up CO2, water and light and produce sugars to survive. “We studied ELMs with photosynthesising algae, which could ultimately be used to deliver oxygen to biological or engineered tissue, where oxygen supply is often a limiting factor for growth.” The artificial engineering of biological tissues is especially important given the growing need for organ transplants.

Controlling growth

“A main limitation that prevents these materials from being used on a larger scale, is that we currently do not know how to control the growth of the cells in these materials. This is what we have investigated. We studied how the growth of cells is affected by the shape of the material, light exposure and access to nutrients and to CO2”, says Aubin-Tam.

“We were also able to show that the cells grew predominantly along the edges of the material where they have better access to air and light”, adds Jeong-Joo Oh, first author of the paper. As such, the researchers found that a thin structure with a large surface area increases the efficiency of the ELMs. In these, a relatively big portion of the cells is found along the edges and therefore in the vicinity of air.

Nature has the answer

Interestingly, nature came to the same conclusion, as the cell growth in the ELM matches how the leaf of a plant is structured. Leaves demonstrate a thin structure with a large surface area to allow a large portion of the cells to be exposed to sunlight. “In our findings, we illustrate that accessibility to light and CO2 is key. Introducing a small opening for gas exchange in the structures visibly improved cell growth in the inner layers. This comes at the cost of accelerated dehydration, however, which is ultimately not good for the cells”, material scientist Masania elaborates. This behaviour too, is analogous to nature. Leaves have very small holes, called stomata. “Like gates, the leaves open their stomata to improve gas exchange whilst not letting too much water escape. Mechanisms that respond to a shortage of CO2, like the stomata of a leaf, would be highly beneficial for the photosynthetic ELMs and increase their longevity and efficiency in the future.”

Interdisciplinary collaboration

In this research, the team studied different shapes of materials and their influence on the cells’ growth. “To allow this, we needed to design a new composition of the ink, the material that comes out of the printer. We were looking for a new ink that would allow us to print larger and more complex objects”, Aubin-Tam explains. While her group at the faculty of Applied Sciences studied the growth of the cells, Masania, from the faculty of Aerospace Engineering, set out to contribute to the development of a new 3D printable ink. Together with Elvin Karana from the faculty of Industrial Design Engineering, they explored the possibilities for producing 3D structures of living photosynthetic materials for future applications.

“The study of cell growth within ELMs is crucial to their efficient use and optimised functionality”, Aubin-Tam concludes. “We hope that our work will motivate biologists, materials scientists, computer scientists and engineers to further investigate cell growth and the properties of this new class of materials.”

Kunal Masania