Making the invisible visible: Micro CT scanner offers 3mE new research opportunities

From bone tissue to metals, and from cells to polymers. TU Delft's Faculty of Mechanical, Maritime and Materials Engineering (3mE) works with a wide range of materials. Recently, researchers have been able to dive even deeper into these materials. The arrival of a micro CT scanner at the faculty allows researchers to explore this invisible world.

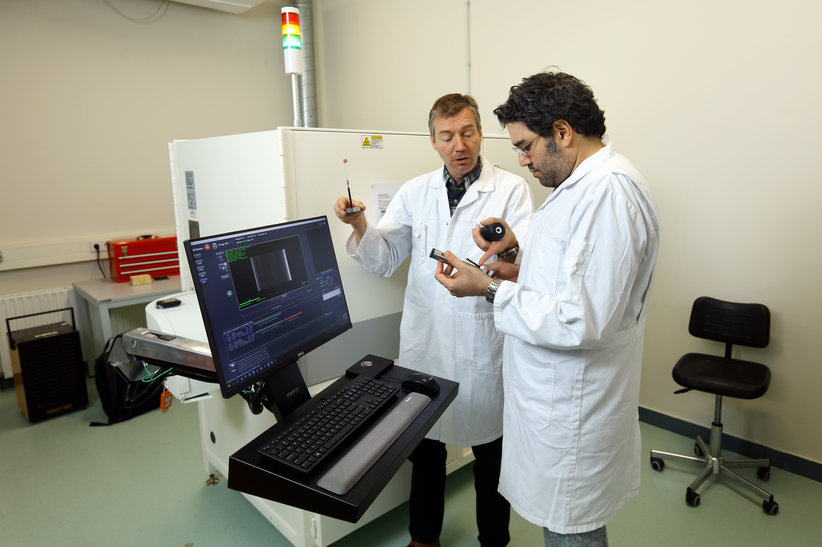

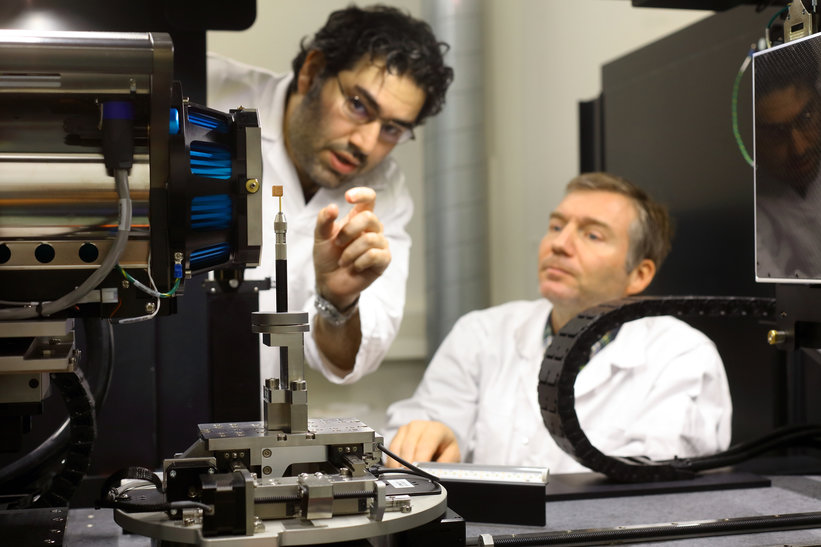

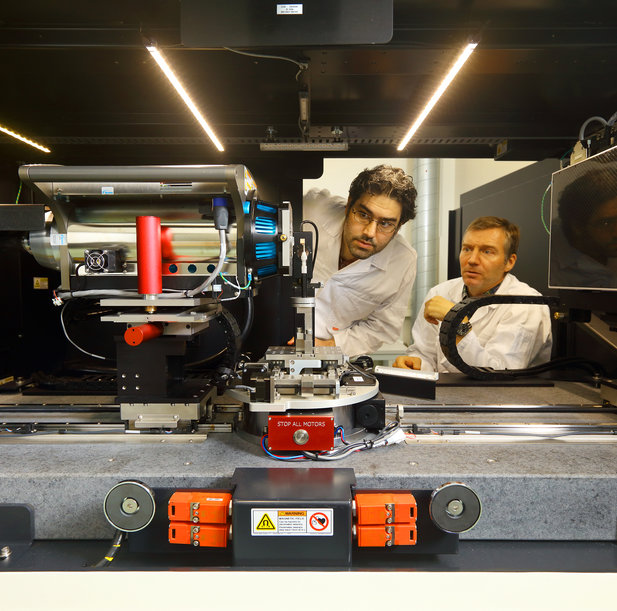

It is a great desire of many researchers to look inside materials without damaging the material. So does researcher Mohammad J. Mirzaali, assistant professor in the Department of Biomechanical Engineering. He studies the transition from hard to soft material, such as the connection between bone and soft tissue in our body. "I want to understand in detail what this transition is made of and how it works. I then use that knowledge to develop better implants," says Mirzaali. The micro CT scanner offers a solution for this. "This allows us to visualise and examine features we couldn't see before, it brings researchers throughout the faculty a lot of new research opportunities."

Costly material

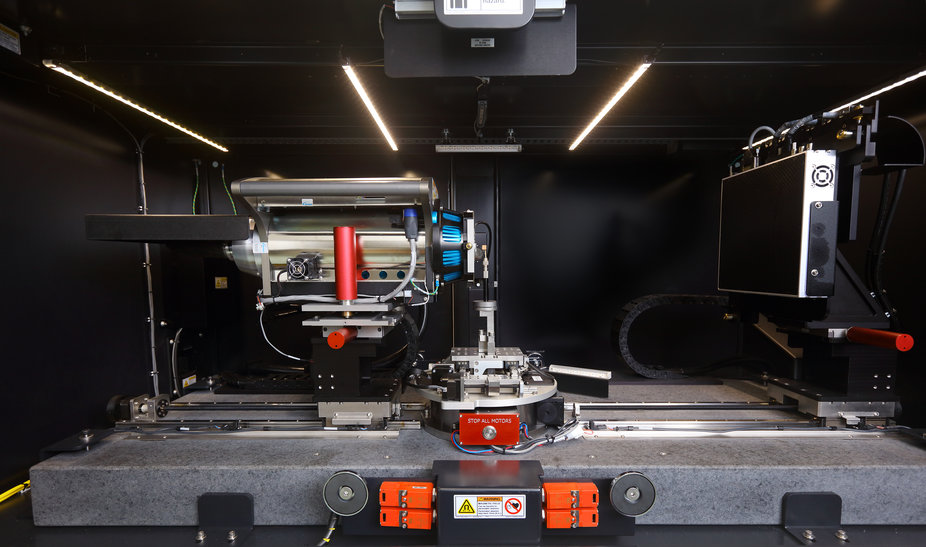

The micro CT scanner operates on X-ray radiation. This allows to examine an object slice by slice and at high resolution in 3D. Samples and specimens can be depicted with a minimum resolution of around one micron. This technique is mainly used to study the internal structure of both materials and biological specimens without having to cut into the samples. This is also useful in the case of Mirzaali's research project. He uses patient-derived bone tissue. "This is costly material that we can now use more sustainably," he says.

From cells to metals

Mirzaali uses the micro CT scanner mainly to study the natural soft-hard interfaces such as bone-tendon connections, their evolution overtime and their interaction with synthetic implants. But the scanner has many more applications. "Colleagues use the scanner to examine the structure of superalloys, polymers or other biological materials.” But it can also be used for quality assurance in 3D printed objects. The technology allows for the assessment of internal microstructures and defects that are not readily visible, thereby ensuring the quality and structural integrity of 3D printed items.

New possibilities

The system also allows for real-time monitoring of materials under varying conditions, such as mechanical loading. In addition, the machine is able to perform both coarse resolution imaging at the larger field of view, and high-resolution local imaging. These dual capabilities offer a significant advantage when performing a multi-scale analysis of materials. “The possibilities with the new scanner are extensive,” says Mirzaali. "We need time to get to know the instrument in order to use its full potential."

A dedicated room has been set up for the micro CT scanner at the 3mE faculty. The scanner will eventually be part of a whole new microbiology lab and will be available to every researcher within 3mE.