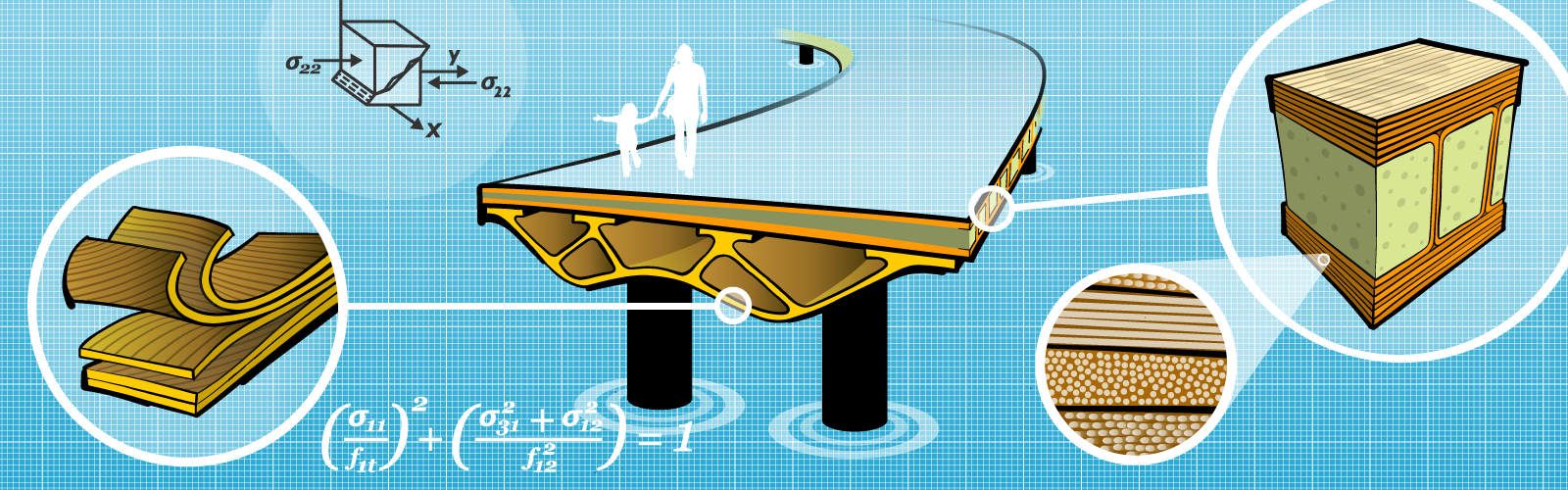

Mechanics and Structures

Technologically-challenging structural applications require a robust system that can reliably perform under demanding conditions.Developing such systems typically involves extensive testing, which is a resource-intensive activity. Simulation-based virtual testing enables to reduce the number of actual tests and accelerate the development process. Virtual testing refers to a combination of numerical and experimental methods for validation and verification that can be applied for new structural and material systems. This environment integrates efficient and accurate numerical methods such as isogeometric analysis, extended finite element methods, multiscale homogenization and reduced-order models together with advanced constitutive material models for inelastic mechanical behavior in order to predict the performance of structures with novel ways of transmitting loads as well as the behavior of materials with enhanced properties. Models for plastic and fracture behavior provide relevant information for design limits and failure performance. Virtual testing enables a cost-effective exploration of a wide range of loading conditions and environments under relevant design requirements (aeroelastic, vibrations, buckling, impact). In conjunction with a coupled-field approach that connects the mechanical behavior with thermal or chemical effects, it is possible to simulate complex phenomena occurring in critical environments such as high-temperature oxidizing conditions or cryogenic temperatures. With the use of relevant models for metals, polymers, ceramics and composite materials, distinct options or combinations thereof can be rapidly analyzed. Advanced design optimization techniques allow to further improve performance,including sensing and actuation. These new methodologies pave the way forward for a concurrent design optimization of materials, structures, sensing and actuation.