First railway project using Delft developed self-healing concrete

A new railway underpass in Rijen, North Brabant, has been partially constructed using self-healing concrete, developed in Delft. This pilot project, commissioned by ProRail, marks a significant milestone in Dutch infrastructure construction. The contractor, Heijmans, is enthusiastic: "The initial findings are positive in every respect."

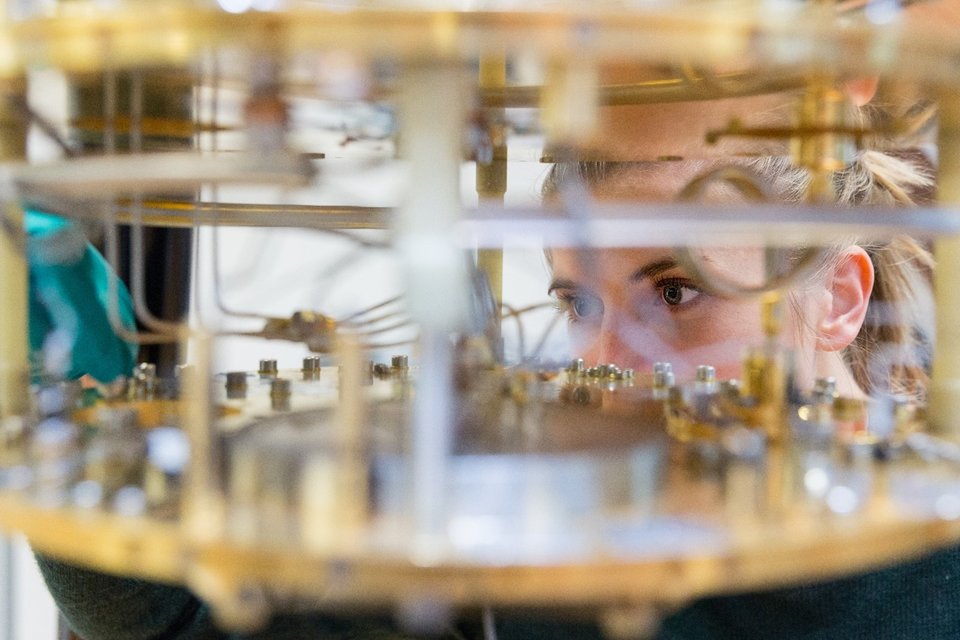

Delft's self-healing concrete can reduce the need for nearly half of the horizontal reinforcement steel regular concrete requires. The key ingredient of this innovation lies in the addition of bacterial spores that deposit limestone. These bacteria become active when water infiltrates concrete, producing limestone that fills cracks in the concrete. As a result, the concrete is better protected from water damage, significantly reducing the need for steel reinforcement, which greatly contributes to lowering the project's CO2 emissions.

Longer Lifespan with less steel

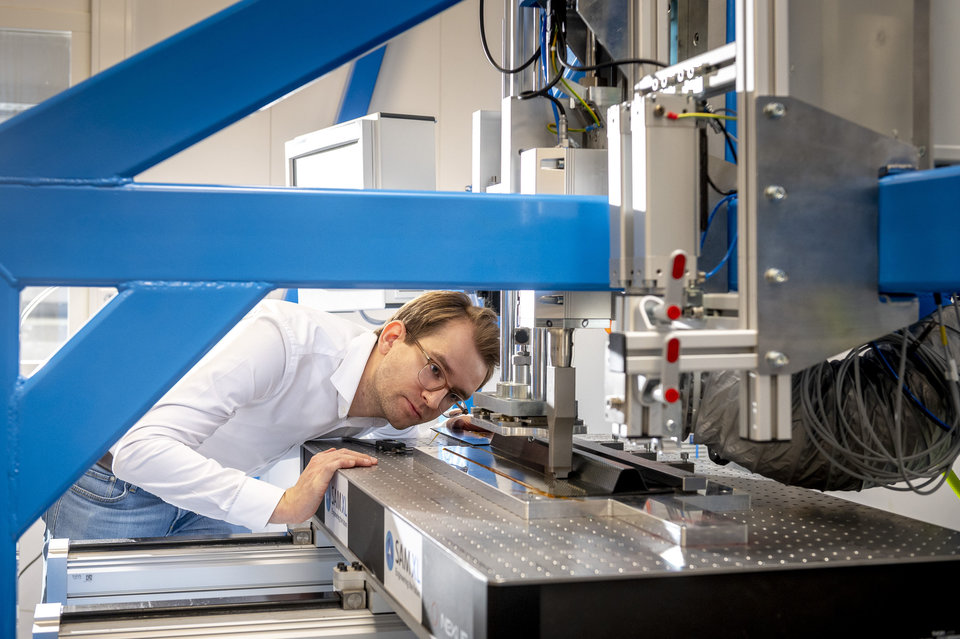

In the Vijfeiken Tunnel in Rijen, a wall of self-healing concrete has been installed in the pump cellar beneath one of the tunnel's access ramps. By incorporating the "healing agent" from the Delft spin-off Basilisk, the amount of horizontal reinforcement steel throughout the 25-meter-long wall has been reduced by 35%. This construction element is expected to require no maintenance and will have a significantly extended lifespan.

The Vijfeiken Tunnel in Rijen is the first Dutch project to combine self-healing concrete with a reduction in horizontal reinforcement. To ensure the added "concrete healing agent" activated as intended, the pump cellar was submerged in water for six weeks after pouring the self-healing concrete. Following this period, the wall was inspected, and concrete samples were tested in the laboratory for self-healing effectiveness. "The initial findings are positive in every respect," states Heijmans.

Industry embracing Delft technology

Bart van der Woerd, managing director of Green Basilisk, is pleased with the leadership shown by the Province of North Brabant, ProRail, and Heijmans. "It is fantastic to see such clients embrace the technology developed at TU Delft and use self-healing concrete."

He highlights the Concrete Agreement, wherein the concrete industry has committed to achieving a 49% reduction in CO2 emissions by 2030. "Green Basilisk's self-healing concrete is one of the innovations contributing to this reduction."

Green Solutions for Major Challenges

Concrete production and usage carry a massive CO2 footprint. To make the concrete industry 100% circular by 2050, innovative solutions need to be tested in real-world applications. Innovations thrive when deployed in large-scale projects. Therefore, TU Delft collaborates closely with start-ups and offers unique testing locations like the regulatory sandbox field lab, The Green Village. Discover more about the solutions being developed in Delft, such as self-healing concrete and new recycling methods that facilitate closing the concrete recycling loop.

![[Translate to English:] [Translate to English:]](https://filelist.tudelft.nl/_processed_/1/b/csm_Breda%20-%20151%20of%20154_scaled_74fd0bc3b8.jpg)